Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

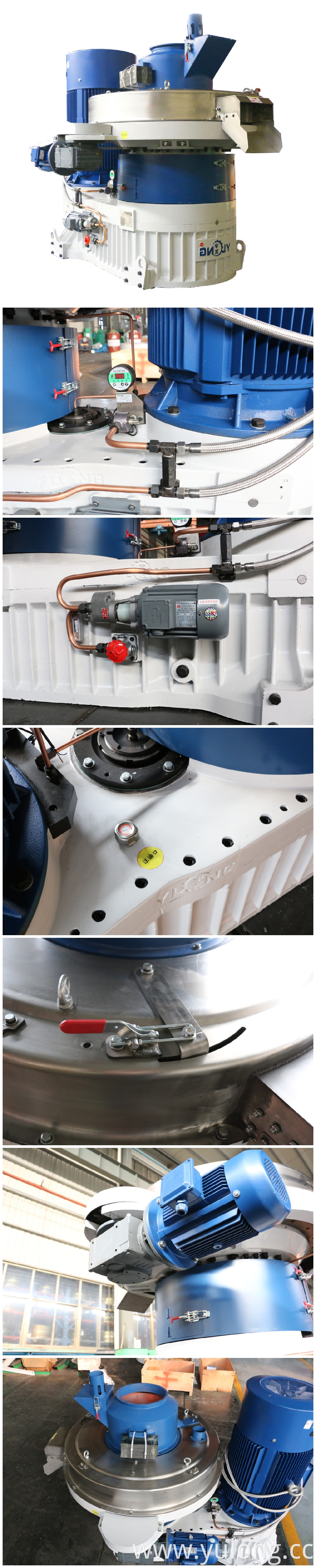

Model No.: XGJ560

Brand: YULONG

Place Of Origin: China

Status: New

Raw Materials Processed: Grass, Rice Husk, Wood Sawdust, Biomass, Straw, Cotton Stalks

Warranty Period: 1 Year

Applicable Industry: Manufacturing Plant, Home Use

Core Selling Point: Easy To Operate, Energy Saving

Out-of-warranty Service: Video Technical Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Malaysia

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Malaysia

Marketing Type: New Product 2020

Mechanical Test Report: Provided

Video Factory Inspection: Not Available

Core Component Warranty Period: 1 Year

Core Components: Motor, Bearing, Gear, Plc, Engine

Capacity: 1-1.5t/H

Spare Parts: Ring Die And Rollers

Name Of The Pellet Machine: Sawdust Pellet Making Machine

Color: Silvery

Packaging: Biomass Pellet Manufacturing Machine : Suitable packing for sea freight

Productivity: 1.5-2T

Transportation: Ocean

Place of Origin: CHINA

Supply Ability: 500 sets/ month

Certificate: ISO9001,CE,SGS

HS Code: 84793000

Port: QINGDAO

Payment Type: T/T,L/C

Incoterm: FOB,CFR,CIF,EXW

Product Categories : Pellet Machine > Wood Pellet Machine

Shandong Yulong Machine Co.,Ltd (Original Hualong Machine Factory)is located in Jinan. Yulong Machine Co.,Ltd is a nation-appointed professional manufacturer of machine for agriculture, forest, pasturage, fishery for many years. Now it becomes a technology enterprise that integrates scientific research, exploitation and manufacture as a whole. This company has not only researched three series of pellet mill, briquette press, crushers, hammer mill, mixer, cooler and pasture machinery but also the complete sets of feed, forest, fertilize, energy machinery equipments with more than ten kinds of high-quality products. They have been exported to Southeast Asian, Europe, Africa, and America, and so on.

Yulong has always mastered the patent and core technology of this product. The appearance of the product is easy to imitate by peers, but the core technology has never been surpassed.

The new generation of biomass pellet machine is more economical and more durable.

Model

Power(KW)

Size (CM) L*W*H

Capacity(T/H)

Weight(T)

8th XGJ560

132+2.2+0.55+0.05+0.15+2.2

2438*1584*1820

1.5-2

5.4

2-XGJ850

250+4+0.05+0.55+3+0.15

2870*1830*2190

3-4

13.6

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.