Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: XGJ560

Brand: Yulong

Voltage: 380V

Automatic Grade: Semiautomatic

Controlling Mode: Artificial

Energy Saving: Energy Saving

Certification: SGS

Warranty: 1 Year

Customized: Customized

Condition: New

Color: Customer Required

Brand: Yulong

Pellet Diameter: 6mm Wood Pellet Machinery

Spare Parts: Mould+ Roller Covers

Moisture: 13%-15%

Application: Press Wood Sawdust Into Pellets

Type: Double Layer Ring Die Pellet Machine

Installation: Guide Your Workers

After-sale Service: Engineers Are Available And Can Appy Visa

Motor: Chinese Famous Brand

Packaging: Suitable for sea freight or air freight

Productivity: 1.5-2t/h

Transportation: Ocean,Air

Place of Origin: Shandong

Supply Ability: 500set per year

Certificate: CE,ISO

HS Code: 84793000

Port: Qingdao

Payment Type: L/C,T/T

Incoterm: FOB,CFR,EXW

Factory Price Pine Chips Pellet Making Machinery

1. Frequency conversion speed-adjusting motor regulating feeding rate, feed screw with variable pitch helical structure, balance feeding and precise control;

2. Conditioner cylinder with large opening structure which is easy to check and maintenance;

3. The conditioner simplified with mist nozzle, it can add proper water as required to make the raw materials achieve the best effect;

4. It can install overboard discharging handle or pneumatic discharging on the chute, which is easy to operate to realize automatic control;

5. Fitting with ring lifting device which is easy to disassembly ring and reduce labor intensity;

6. Large machine adopts magnetic filtering, cooling and fuel cut alarm in a whole of the machine oil cooling lubrication system, force to lubricate main bearing, hollow shaft rear bearing and gear shaft rear bearing;

7. According to the ring die speed of material, improve pellet effect.

Yulong Wood Pellet Mill in Vietnam-- Yulong Pellet Mill can be used to press wood sawdust, rice husk, straw etc into pellets as biomass fuel.For this kind of materials, the the Pellet Production Line can include rotary screener to seperate stones and sand, then use yulong Pellet Machine to press them. Certainly, it is required the all materials moisture before to be pressed about 15%. Higher humidity less moisture,the pellets quality not good.

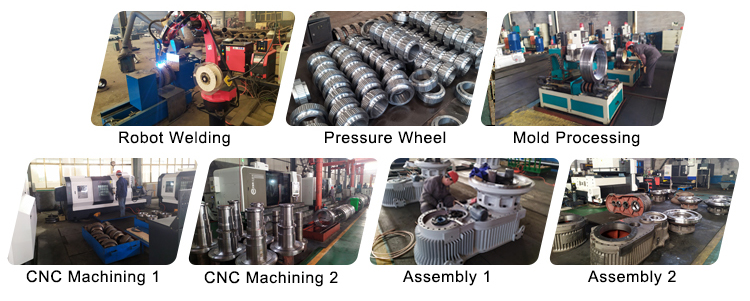

Double layer Ring Die Pellet Machine is produced by chief engineer of Shandong Yulong Machine Co., Ltd who also manufactue other equipments like Wood logs chipper, wood chips Hammer Mill, sawdust rotary screener, cooler and packing system etc. Vertical Ring Die Rice Husk wood pellet mill is our patent product(Patent NO. ZL 2010 1 0571769.0), it can press wood sawdust into pellets, also can press rice husk into biomass pellets for fuel.

Double layer ring die Vertical Ring Die Rice Husk Wood Pellet Mill is designed by our chief engineer. If you want to do biomass pellet making line, welcome visit our company, you will get more than you learned by yourselves.

Yulong Wood Pellet Mill in Vietnamyulong equipments certification

132KW Peanut Shell Pellet Machine working condition

Vertical Ring Die Rice Husk Wood Pellet Mill is by-product from wood sawing process. Actually, sawdust doesn`t have much application because of its low burning efficient. However, by pressing the saw dust into pellets, it becomes a kind of high quality bio fuel product – sawdust pellets or wood pellets.

Vertical Ring Die Rice Husk Wood Pellet Mill Strengthen the transmission system

1.Deceleration structure :transmission with parallel shaft three hardened teeth helical slowdown,gear modulus increase,gear widening,strengthening,transmission strength is 3-5 times the conventional reducer.

2.Power input:the use of efficient energy-saving motor,plug directly connected,coaxial high,high-speed shaft with parallel shaft structure,gear shaft are two support rotation,high rigidity,smooth and reliable transmission,to abandon the greater power.

3.Power output:the deice output and the spindle into one,to abandon the limited form of connection,the strength increased 2-3 times.

4.Main shaft strengthening:the shaft length is shortened,the stiffness is significantly improved,high stiffness of the shaft can reduce the wear of mold and rollers.

5.Flexible installation:the device outlet can be multi-angle rotation,equipment installation more flexible and diverse.

Vertical Ring Die Rice Husk Wood Pellet Mill produce process:

Vertical Ring Die Rice Husk Wood Pellet Mill Specifications:

| Model | Power (kw) | Capacity for wood pellets(kgs/h) | Weight of the machine(kgs) | Dimension of the machine (mm) |

| XGJ560 | 90+1.5+0.37+1.5 | 1000-1500 | 5300 | 2600x1300x2300 |

| XGJ560-6th | 132+1.5+0.37+1.5 | 1500-2000 | 4600 | 2100x1700x1600 |

| XGJ850 | 220+3+0.37(0.55)+2.2 | 2000-3000 | 14500 | 3300x1400x3100 |

| XGJ850-6th | 220+3+0.37(0.55)+2.2 | 2500-3500 | 9600 | 2600x1600x1950 |

| XGJ920 | 315+5.5+0.55+1.5+2.2 | 3000-4000 | 18000 | 3800x1680x3400 |

| XGJ1050 | 450+5.5+0.55+1.5+3 | 5000-6000 | 23000 | 3980×2060×3450 |

Vertical Ring Die Rice Husk Wood Pellet Mill yulong team

Product Categories : Pellet Machine > Sawdust Pellet Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.