Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: XGJ560

Brand: YULONG

Voltage: 380V

Automatic Grade: Semiautomatic

Controlling Mode: Artificial

Energy Saving: Energy Saving

Certification: SGS

Warranty: 1 Year

Customized: Customized

Condition: New

Color: Customer Required

Brand: Yulong

Spare Parts: Mould+ Roller Covers

Moisture: 13%-15%

Application: Press Wood Sawdust Into Pellets

Type: Double Layer Ring Die Pellet Machine

Installation: Guide Your Workers

After-sale Service: Engineers Are Available And Can Appy Visa

Motor: Chinese Famous Brand

Pellet Diameter: 6-8mm

Packaging: Suitable for sea freight or air freight

Productivity: 1.5-2t/h

Transportation: Ocean,Air

Place of Origin: Shandong

Supply Ability: 500 setS per year

Certificate: CE,ISO

HS Code: 84793000

Port: Qingdao,China

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

Features of Straw hay Pellet Making Machine

1. Straw hay pellet making machine can work for 24 hours continuously, no need to stop.

2. Biomass Pellet Machine with one set ring die and two roller assembly.

3. Vertical feeding directly in place.

4. Die static, roller rotating,material centrifugal, evenly distributed around.

5. Double layer dies, up and down dual sue, reduce the cost, enhence the efficiency.

6. One die, different hold diameters, with different specification to pelletizer.

7. biomass pellet machine always work with automatic lubricate system, fan blower, bag dust collector. Firstly, clean dust, very enviromental proteciton. Secondly , it can cool Pellet Machine inner spare prts heat treatment, making sure long continuous working time.

8. Biomass Sawdust Pellet Machine had two layer dies. Both upside and down side can be used. So life span is two times higher than the normal ones.......

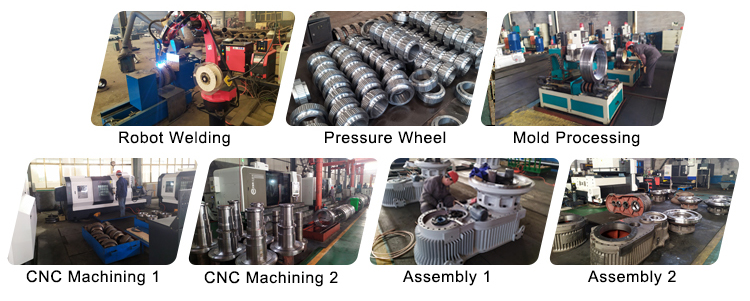

9. Biomass Pellet Making Machine spare parts are made by CNC system, through high technical heat treatment, HRC larger than 50 degree. Greatly welcome to ask me for more details.

10. Biomass pellet making machine middle part are casted-steel, which can give the machine body a strong support. So machine are very stable when it works.....

Straw is a common kind of agricultural material in our countryside. We will have many straw material in harves season. How we can do to solve them? to burn them in the field or as animal or poultry feeding. Now a new method to solve them is to press them into biomass pellets. The straw pellets price is much cheaper then wood pellets, also very convenient for storge and transport compare to the straw.

XGJ series efficient centrifugal straw hay pellet machine is our main product which has adopted the essence of Pellet Mill in oversea market.The heart parts [double layer die" has unique structural assembly and "rollers" are made of high wearable alloy materials.These two parts have the following characters:particular design,reasonable structure,low energy,high efficiency,long lift and so on.Through many technical experts hard work,our company has developed this typical patent product which comes forth firstly in domestic market.The new machine has filled the country blank in vertical feeding for Ring Die Pellet Mill and reached the international advanced level.

Yulong Brand straw hay pellet machine advantages

| √ | Vertical ring die wood sawdust Straw Pellet Mill , feeding vertically, the raw materials can follow to the pellet machine room directly. pellet machinery companies in china |

| √ | Vertical ring die structure, easy for heating dissipation, which can keep the machine running continually. |

| √ | Ring die fixed, main axis vertically, main shaft and roller rotating , the roller only can rotating inside of the ring die, so no deflection, no shaking, machine running more stably. |

| √ | Vertical ring die fixed, roller rotating, with centrifugal force, making the materials evenly distributed around inside the die, also the centrifugal force will help improve the capacity. |

| √ | Double-layer stainless steel ring die, up and down side. One ring die can be using 2 times by turn it over. Cut down operating costs pellet machinery producers |

| √ | Sixth-generation centrifugal vertical Ring Die Pellet Machine reducer is replaced by big gear which is specially designed by our engineer Chinese pellet mill producers |

Yulong straw hay pellet m 1ton/h Specifications:

| Model | Power (kw) | Capacity for wood pellets(kgs/h) | Weight of the machine(kgs) | Dimension of the machine (mm) |

| XGJ560 | 90+1.5+0.37+1.5 | 1000-1500 | 5300 | 2600x1300x2300 |

| XGJ560-6th | 132+1.5+0.37+1.5 | 1500-2000 | 4600 | 2100x1700x1600 |

| XGJ850 | 220+3+0.37(0.55)+2.2 | 2000-3000 | 14500 | 3300x1400x3100 |

| XGJ850-6th | 220+3+0.37(0.55)+2.2 | 2500-3500 | 9600 | 2600x1600x1950 |

| XGJ920 | 315+5.5+0.55+1.5+2.2 | 3000-4000 | 18000 | 3800x1680x3400 |

| XGJ1050 | 450+5.5+0.55+1.5+3 | 5000-6000 | 23000 | 3980×2060×3450 |

Our company profile

Yulong Palm Fibre Pellet Press Machinery is by-product from wood sawing process. Actually, sawdust doesn`t have much application because of its low burning efficient. However, by pressing the saw dust into pellets, it becomes a kind of high quality bio fuel product – sawdust pellets or wood pellets.

Yulong Pellet Mill Machine 1ton/h Strengthen the transmission system

1.Deceleration structure :transmission with parallel shaft three hardened teeth helical slowdown,gear modulus increase,gear widening,strengthening,transmission strength is 3-5 times the conventional reducer.

2.Power input:the use of efficient energy-saving motor,plug directly connected,coaxial high,high-speed shaft with parallel shaft structure,gear shaft are two support rotation,high rigidity,smooth and reliable transmission,to abandon the greater power.

3.Power output:the deice output and the spindle into one,to abandon the limited form of connection,the strength increased 2-3 times.

4.Main shaft strengthening:the shaft length is shortened,the stiffness is significantly improved,high stiffness of the shaft can reduce the wear of mold and rollers.

5.Flexible installation:the device outlet can be multi-angle rotation,equipment installation more flexible and diverse.

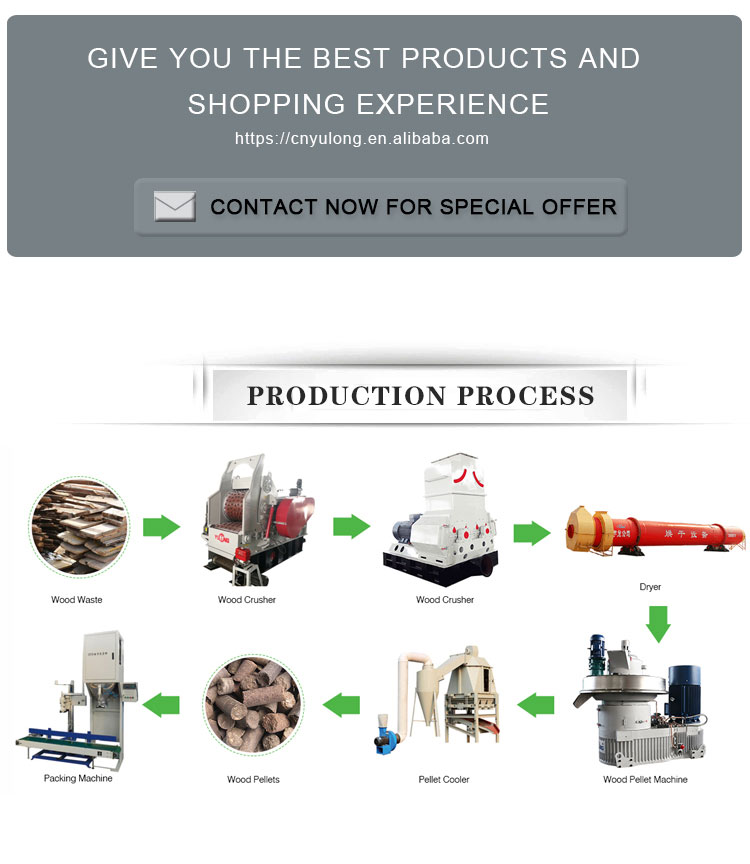

Yulong pellet mill 1ton/h produce process:

Product Categories : Pellet Machine > Biomass Pellet Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.